Ball Mill Volume Perhitungan

مجال التطبيق

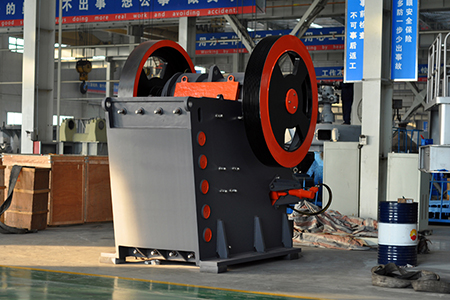

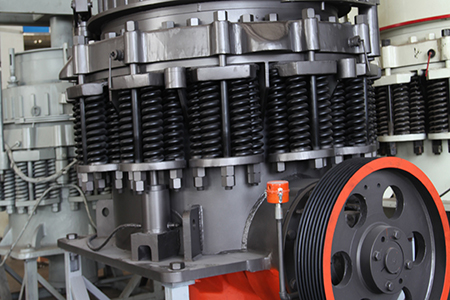

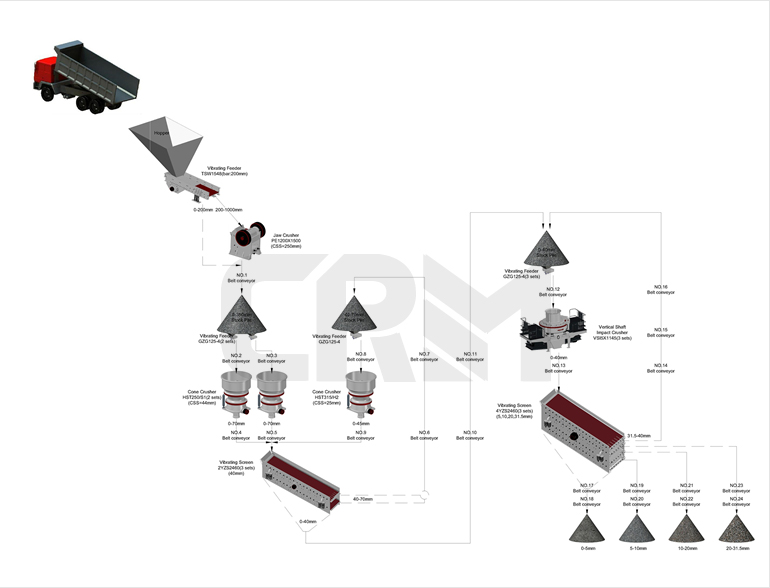

خط إنتاج معالجة البوكسيت 200TPH في غينيا

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

Mill Steel Charge Volume Calculation

2015-6-19 While the mill is stopped, the charge volume can be gotten by measuring the diameter inside the liners and the distance from the top of the charge to the top of the mill. The % loading or change volume can then be read off the graph below or approximated from the equation and calculation: % Steel Charge Loading in Mill = 113 – 126 H/ D . Ball ...

Calculate Ball Mill Grinding Capacity - Mineral Processing

2015-10-15 A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling

Menentukan-Menghitung Jumlah Ball Mill. - ardra

2022-5-13 Contoh Soal Perhitungan Menentukan Jumlah Ball Mill. Ardra.Biz, 2019, “data Dimensi Ball Mill dan Variabel Operassi Ball Mill. Diameter mill D, Panjang mill L, Charge (%) ball mill, rasio volume muatan terhadap volume ball mill. Jenis Ball Mill dan Rod Mill

Ball Mill Design/Power Calculation

2015-6-19 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of

Ball Mills - Mineral Processing Metallurgy

2017-2-13 CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.

Cara Menghitung Ball Mill Loading

2021-8-4 Perhitungan Ball Mill Menghitung Daya Listrik Crusher Dan Ball Mill. ardra. Perhitungan Kebutuhan Daya Listrik Pada Kominusi. Hitung daya yang diperlukan jika suatu pabrik pengolahan batu kapur yang berkapasitas 100 Doc Tarif Tambat Labuh Kapal Budi

AMIT 135: Lesson 7 Ball Mills Circuits - Mining Mill

For overflow ball mills, the charge should not exceed 45% of the mill volume . For grate discharge mills, the charge should occupy about 50% of the mill volume . Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R, i.e.,

rumus putaran ballmill

2022-5-1 Ball Mill merupakan alat Industri yang sangat berperan penting dalam Kecepatan putaran penggiling berbanding lurus dengan energi yang akan dihasilkan Semakin tinggi kecepatan putaran energi yang akan dihasilkan juga Landasan teori berisi tentang rumus dasar dan variablevariable pengaruh yang dipakai dalam penelitian ini.

PERANCANGAN BALL MILL KAPASITAS 200 mg

2016-10-6 Perancangan ini bertujuan untuk mendapatakan rancangan ball mill yang sesuai dengan perhitungan untuk mendapatakan dimensi komponen ball mill. Perancangan ball mill ini di mulai dari menentukan volume tabung ball mill, dari penentuan volume tabung ...

Ball Mill Design/Power Calculation

2015-6-19 Ball Mill Power Calculation Example #1. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns). The required product size distribution is to be 80% passing 100 mesh (149 microns). In order to determine the power requirement, the steps ...

Ball Mill: Operating principles, components, Uses,

2020-7-5 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size.

Cara Menghitung Ball Mill Loading

2021-8-4 Perhitungan Ball Mill Menghitung Daya Listrik Crusher Dan Ball Mill. ardra. Perhitungan Kebutuhan Daya Listrik Pada Kominusi. Hitung daya yang diperlukan jika suatu pabrik pengolahan batu kapur yang berkapasitas 100 Doc Tarif Tambat Labuh Kapal Budi

AMIT 135: Lesson 7 Ball Mills Circuits - Mining Mill

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns.; The Center-Periphery Discharge mill has feed reporting from both ends and the product

PERANCANGAN BALL MILL KAPASITAS 200 mg

2016-10-6 Perancangan ini bertujuan untuk mendapatakan rancangan ball mill yang sesuai dengan perhitungan untuk mendapatakan dimensi komponen ball mill. Perancangan ball mill ini di mulai dari menentukan volume tabung ball mill, dari penentuan volume tabung ...

Perhitungan Biaya Machine Ball Mill

2022-1-10 Perhitungan untuk ball mill 2011 izolacjenatryskowe perhitungan mesin grinding vivekanandbcaorgerhitungan biaya proses milling mesin crusher, kata kunci, offshore technology ari mesin stone crusher di in perhitungan pada vertical mill techasia analisis

RANCANG BANGUN BALL MILL DARI BAJA DIAMETER ...

2019-10-4 Jurnal Forum Nuklir (JFN) Volume X, Nomor X, Bulan Terbit XXXX (JFN Header) 20 Desain dan Perhitungan 𝑛1 = 2 𝑛2 den 1 gan : n1 = putaran pulley 1 (rpm) n2 = putaran pulley 2 (rpm) d2 = diameter pulley 2 (cm)

Rumus Perhitungan Pisau Hammer Mill Stolz

2021-7-6 Rumus Perhitungan Volume Screw Feeder perhitungan waktu proses mesin cnc milling - pemasok rumus perhitungan volume screw feeder. processed materials: brick, dolomite, sphalerite, etc fob price: us $8700 - 105000 / set. mtw series trapezium mill mtm

Perhitungan Grinding Case

2021-12-25 Perhitungan Ball Mill Indonesia Penghancur perhitungan gear ratio belt conveyor - Project Case. penyebab kerusakan mesin ball mill perhitungan power motor crusher ... analisis perhitungan grinding machine, grinding mill plant ... Perhitungan efisiensi panas

UNIVERSITAS INDONESIA SIMULASI DENGAN METODE ...

2010-7-7 UNIVERSITAS INDONESIA SIMULASI DENGAN METODE MONTE CARLO UNTUK PROSES PEMBUATAN NANOMATERIAL MENGGUNAKAN BALL-MILL SKRIPSI FAHLEFI NUR DIANA 0305020381 FAKULTAS MATEMATIKA DAN ILMU PENGETAHUAN

Ball Mill Design/Power Calculation

2015-6-19 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of

Ball Mill Explained - saVRee

For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 30-45%). Pulp (crushed ore and water) fills another 15% of the drum’s volume so that the total volume of the drum is 50% charged. Pulp is usually 75% solid (crushed ore) and 25% water; pulp is also known as ‘ slurry ’.

The working principle of ball mill - Meetyou Carbide

2019-5-22 The ball ratio is usually selected from 2:1 to 5:1. In some cases, a large ball-to-batch ratio is used. For example, a wet-milled titanium carbide-based carbide bar can be used for 6:1. Because the volume of the mixture is large at this time. It seems that using the ball to material volume ratio to indicate the amount of charge will be more ...

Cara Menghitung Ball Mill Loading

2021-8-4 Perhitungan Ball Mill Menghitung Daya Listrik Crusher Dan Ball Mill. ardra. Perhitungan Kebutuhan Daya Listrik Pada Kominusi. Hitung daya yang diperlukan jika suatu pabrik pengolahan batu kapur yang berkapasitas 100 Doc Tarif Tambat Labuh Kapal Budi

AMIT 135: Lesson 7 Ball Mills Circuits - Mining Mill

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns.; The Center-Periphery Discharge mill has feed reporting from both ends and the product

UNIVERSITAS INDONESIA SIMULASI DENGAN METODE ...

2010-7-7 UNIVERSITAS INDONESIA SIMULASI DENGAN METODE MONTE CARLO UNTUK PROSES PEMBUATAN NANOMATERIAL MENGGUNAKAN BALL-MILL SKRIPSI FAHLEFI NUR DIANA 0305020381 FAKULTAS MATEMATIKA DAN ILMU PENGETAHUAN

pertimbangan sistem ball mill design

The process firstly conducted was to choose electric motor and inverter Get Price semen ball mill desain kapasitas perhitungan ball mill More Reading 3D Animation Demo amp working site of Ball Mill nbsp 0183 32 3D Animation Demo amp working ...

Perhitungan Grinding Case

2021-12-25 Perhitungan Ball Mill Indonesia Penghancur perhitungan gear ratio belt conveyor - Project Case. penyebab kerusakan mesin ball mill perhitungan power motor crusher ... analisis perhitungan grinding machine, grinding mill plant ... Perhitungan efisiensi panas

PENDUGAAN REDUKSI UKURAN BERBASIS MODEL ...

volume Ball-Mill yang digunakan. Alat utama yang digunakan pada penelitian ini adalah Ball mill tipe batch dengan diameter 25 cm dan panjang 30 cm digunakan untuk proses penepungan. Rotasi dari ball mill diperoleh dari motor listrik 2 HP yang

RETSCH – Laboratory Mills, Crushers and Sieve Shakers

Laboratory Mills, Crushers and Sieve Shakers. RETSCH is the leading solution provider for neutral-to-analysis sample preparation and characterization of solids. Based on a century of experience RETSCH develops size reduction and sieving equipment which is characterized by excellent performance, operating convenience, safety and a long lifetime.

سابق: سعر كسارة الحجر الجيري في غانا

التالي: مخروط محطم الذهب خام محطم

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت