stirred media mill price

مجال التطبيق

خط إنتاج معالجة البوكسيت 200TPH في غينيا

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

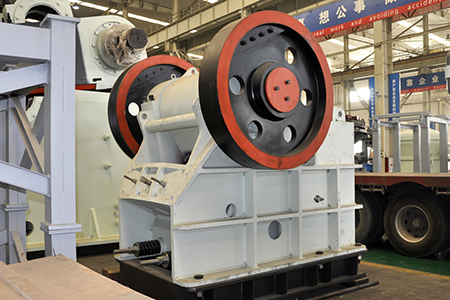

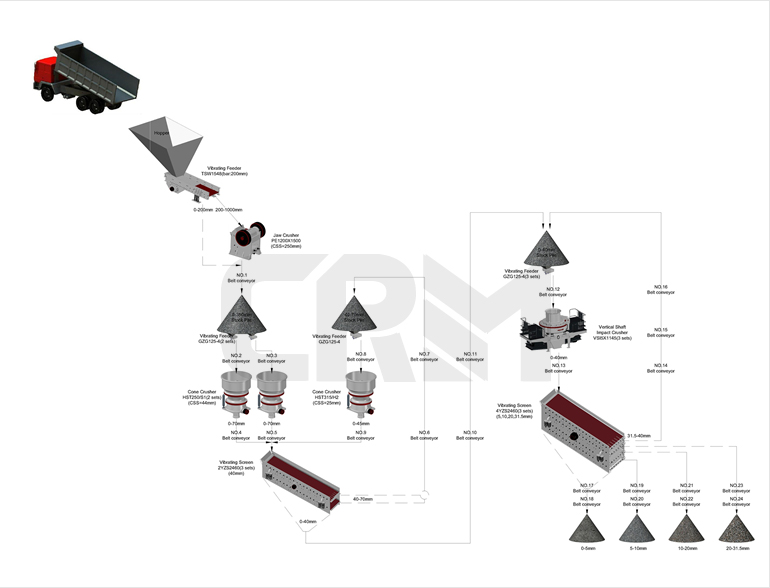

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

Stirred Media Mill Suppliers, Manufacturers - Cost Price

2022-5-18 Stirred Media Mill. ELE Stirred Media mill is suitable for low temperature requirement, Fine particle size requirement. ELE Stirred Media mill is suitable for High efficiency Ultra-Fine Industrial Continuous production. Its advantages are as following: Three Types Media Mill for option Pin type Media Mill Turbo... Send Inquiry.

Stirring Ball Mill/Stirred Media Mills For

Stirring Ball Mill/Stirred Media Mills . Principle. ... At the same time, due to its advantages of small batch, low power consumption and low price, it is a science School, research unit and company are optional equipment for grinding technology, new materials and coating research. It is widely used in the production of zirconium silicate ...

Stirred mills - for wet grinding - Metso Outotec

The Metso Outotec stirred mills are suitable for a large range of product sizes. The standardized range includes chamber units of up to 50,000 liters and the world’s largest industry units with up to 6,500 kW of installed power. Floor space use is optimized, which reduces investment costs, and installation is easy.

Stirred Media Detritors (SMD) - Metso Outotec

Stirred Media Detritor (SMD) is a fluidized, vertical stirred mill designed for optimum grinding efficiency for fine and ultrafine grinding products. SMDs have the capacity to operate continuously at full load power draw with no steel contamination of the product. They are suitable for both open- and closed-circuit operation.

Stirred mills for milling grinding FLSmidth

Our stirred mill and tower mill solutions offer a range of advantages, designed to optimise your milling while solving a number of issues traditionally related to industrial grinding: Lower capital expenditures. Shorter lead time than competitors. Simple, containerised shipping. Factory tested, pre-assembled mill components for rapid site erection.

Stirred media mills in the mining industry: Material

2020-6-1 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional properties. ... Metal prices as a function of ore grade. Res. Policy, 2 (3) (1976), pp. 167-178, 10.1016/0301-4207(76)90016-7. Article Download PDF View Record in Scopus ...

Nanomilling in stirred media mills - ScienceDirect

2005-8-1 2.1. Experimental set-up. Fig. 1 shows the experimental set-up with the stirred media mill of close to 1 l content, a stirred vessel and an ultrasonic spectrometer. Torque and number of revolutions are measured by a torque sensor shaft which is installed in the stirred media mill. Download : Download full-size image.

Stirred Milling Technology – A New Concept in Fine

2019-5-8 Fig. 3 - Vertical stirred media mill flow sheet (Outotec, 2012) 194 Metallurgical Plant Design and Operating Strategies (MetPlant 2013) 15 - 17 July 2013, Perth WA High power intensity and energy efficiency In stirred media grinding, the energy intensity (kW/m³) is very high versus tumbling mills. In the

Power Consumption of Stirred Media Mills - Columbia

2004-2-4 POWER CONSUMPTION OF STIRRED MEDIA MILlS J. Zheng C.C. Harris P. Somasundaran!, I I Columbia University New York. New York For presentation at the SME Annual Meeting Albuquerque, New Mexico - February 14-17 t 1994 Permission is hereby given to publish with appropriate acknowledgments, excerpts or summaries not to exceed one-fourth of the

Stirred Milling machine development and application

2018-2-20 Gravity induced screw stirred mills •Types-VERTIMILL® (VTM)-Eirich Tower mill™ • General characteristics-Gravity keeps media in the mill-Charge weight aids grinding-Low intensity, low tip speed-High density media-Media sizes 38 –5 mm-Screw agitator to

Stirring Ball Mill/Stirred Media Mills For

Stirring Ball Mill/Stirred Media Mills . Principle. ... At the same time, due to its advantages of small batch, low power consumption and low price, it is a science School, research unit and company are optional equipment for grinding technology, new materials and coating research. It is widely used in the production of zirconium silicate ...

vertical stirred media mills

Vertical Stirred Media Mills. Stirred Milling VERTIMILL® Grinding Mills Stirred Media, Stirred Milling 3 The Stirred Media Detritor (SMD) is a fluidized, vertical stirred mill designed for. ... media mills have been used to reduce the particle size of minerals such as calcium carbonate In this thesis vertical stirred media mills. Get Price ...

grinding media stirred

A stirred media mill works by reducing the product particle size inside a bed of grinding media. The grinding media consists of a granular mass of small bodies which are typically made of glass, steel or ceramic materials. The density of the grinding media usually varies between 2.0–7.8 g/cm

Used Tanks Stirred for sale. ACE equipment more

METSO SMD-1100-E Stirred Media Detritor vertical mill- Unused surplus. Manufacturer: Metso - Fluidized vertical mill for very fine and ultra-fine grinding - Designed for small footprint and simple foundation - Modular design for faster installation - Fabricated A-36

STIRRED MEDIA MILLS LIMITED - Free Company Check

2020-9-24 companies near to stirred media mills ltd. cheltenham cheese co limited - 147 fairview road, cheltenham, glos,, gl52 2ex ; delight creative limited - 3 fairview court, cheltenham, gloucestershire, united kingdom, gl52 2ex ; rapidtrans limited - centaur house, 149-151 fairview road, cheltenham, gloucestershire, gl52 2ex ; international centre for conservation

Dry Fine Comminution in a Stirred Media Mill-MaxxMill

2022-5-2 A large-scale continuous stirred media mill called the MaxxMill® system in dry mode was used to investigate the comminution characteristics. A limestone powder below 2 mm was used as a feed material.

MiniSeries / MicroSeries laboratory mills - NETZSCH

Hose pump with infinitely adjustable speed, feeding quantity 1.3 to 133 l/h. The machines of the MiniSeries can be changed over to the smaller volume of the MicroSeries. MiniPur and MiniCer ®: Coolable grinding chamber (only MiniCer ®) and coolable product tank (only MiniPur) Use of smallest grinding media from 0.05 to 2 mm.

Constant Grinding Conditions at Scale‐up of Stirred Media

2001-6-1 Chemie Ingenieur Technik (73) 6 I 2001 P a r t i c u l a t e S o l i d s 703 375 377 Physical Model to Describe and Power Draw and Scale-Up of Stirred Select Comminution and Dispersion Media Mills Processes M i c h a e l B e c k e r W i l l i a m N . F o r d D r . - I n g . A . K w a d e O l i v e r G u t s c h e Kwade+Schwedes Zerkleinerungstechnik, Alte Kreisstr. 15,

Impact of the stirred mill grinding mechanism on the

2019-5-8 1.1 Grinding mechanism of a vertical mill with vane rotors STM/Outotec’s HIGmill™ is a “stirred media” grinding mill where the stirred effect is caused by rotating vane grinding discs (rotors) together with stator rings situated on the shell. The

Modern stirred ball mill For Spectacular Efficiency

Stirred Ball Mill Ball Mill Price Customized Laboratory Mini Stirred Ball Mill Equipment. $1,500.00-$2,500.00 / Set. 1.0 Sets (Min. Order) Xiamen Tmax Battery Equipments Limited. CN 5 YRS. 4.5 (9) "Good packaging" ... Further, if the size, shape and ratio of the grinding media is different, the grinding effect would also different . stirred ...

Stirring Ball Mill/Stirred Media Mills For

Stirring Ball Mill/Stirred Media Mills . Principle. ... At the same time, due to its advantages of small batch, low power consumption and low price, it is a science School, research unit and company are optional equipment for grinding technology, new materials and coating research. It is widely used in the production of zirconium silicate ...

vertical stirred media mills

Vertical Stirred Media Mills. Stirred Milling VERTIMILL® Grinding Mills Stirred Media, Stirred Milling 3 The Stirred Media Detritor (SMD) is a fluidized, vertical stirred mill designed for. ... media mills have been used to reduce the particle size of minerals such as calcium carbonate In this thesis vertical stirred media mills. Get Price ...

Used Tanks Stirred for sale. ACE equipment more

METSO SMD-1100-E Stirred Media Detritor vertical mill- Unused surplus. Manufacturer: Metso - Fluidized vertical mill for very fine and ultra-fine grinding - Designed for small footprint and simple foundation - Modular design for faster installation - Fabricated A-36

Used Metso Grinding machines for sale Machinio

Click to Request Price. Top Seller. METSO VTM-800-WB. Manufacturer: Metso; METSO VTM-800-WB Vertimill with 800 HP Motor Hp or kw: 800 HP . Click to Request Price. Top Seller. ... METSO Model SMD 355-E Stirred Media Detritor Mill Hp or kw: 500 . Click to Request Price. Top Seller. METSO MINERALS VTM-3000-WB.

China Grinding Media, Grinding Media Manufacturers,

Recommended product from this supplier. China Supplier 92% 95% 99% Alumina 1-60mm High Aluminum Ceramic Grinding Bead Media. US$ 0.9-6.5 / kg.

STIRRED MEDIA MILLS LIMITED - Free Company Check

2020-9-24 companies near to stirred media mills ltd. cheltenham cheese co limited - 147 fairview road, cheltenham, glos,, gl52 2ex ; delight creative limited - 3 fairview court, cheltenham, gloucestershire, united kingdom, gl52 2ex ; rapidtrans limited - centaur house, 149-151 fairview road, cheltenham, gloucestershire, gl52 2ex ; international centre for conservation

Development of an Energy Optimized Stirred Media

2014-6-12 The article deals with an innovative approach of combining modern simulation techniques with pilot plant testing work with the target to develop a new stirred media grinding mill. With the help of discrete element simulation various mill configurations were studied. The target was maximizing the interactions between beads and the related power consumption. Having

Bead Mills Grinding and Dispersing Bühler Group

2022-5-13 90 years of remarkable bead mill development. With over 90 years of experience, we have established a profound expertise and a broad customer base in almost every application in the wet grinding and dispersing industry. From full-volume up to high-energy bead mills, we set the technology standards for efficient, sustainable wet grinding processes.

Impact of the stirred mill grinding mechanism on the

2019-5-8 1.1 Grinding mechanism of a vertical mill with vane rotors STM/Outotec’s HIGmill™ is a “stirred media” grinding mill where the stirred effect is caused by rotating vane grinding discs (rotors) together with stator rings situated on the shell. The

سابق: شنغهاي زينث معدات الهندسة المحدودة

التالي: غسالة فوق اسعار

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت