continuous casting machine

مجال التطبيق

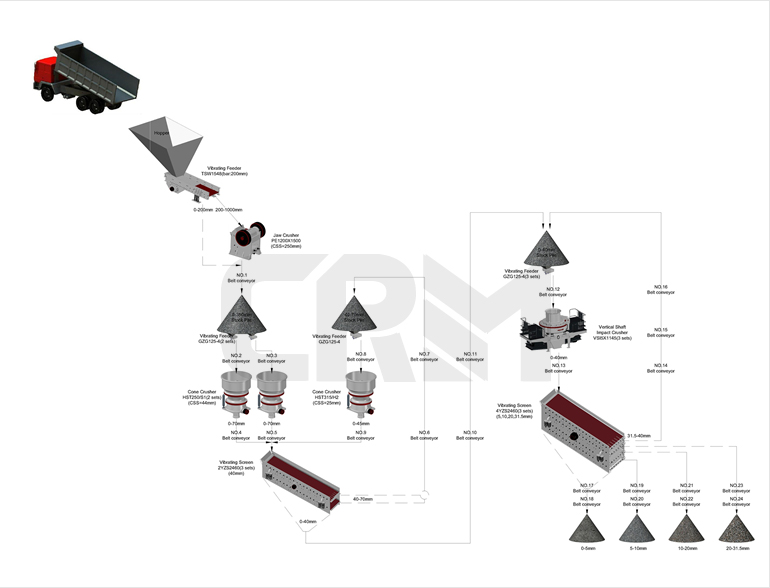

خط إنتاج معالجة البوكسيت 200TPH في غينيا

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

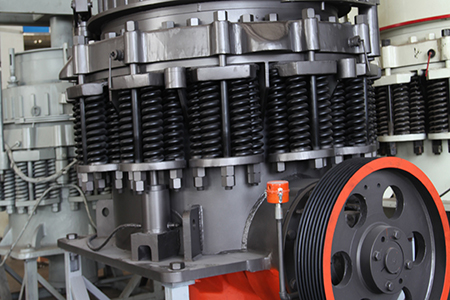

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

Continuous Casting Machines - voestalpine Stahl Donawitz

2022-5-11 The new bloom continuous casting machine CC4 will be the new heart of steel production in Donawitz in 2020. This is the world's most modern and fully digitized system of its kind and offers premium quality through a globally unique combination of plant and process technology. Further continuous casting systems are the CC3 continuous casting ...

Continuous Casting Machine - Continuous

2019-12-19 Continuous Casting Machine. The horizontal continuous casting machine’s crystallizer, secondary cooling zone, tension leveler, cutting equipment and other equipment are in the horizontal orientation, and the center package

Continuous Casting Machines and their Types –

2019-7-13 Continuous casting (CC) is a process of producing an infinite solid strand from liquid steel by continuously solidifying it as it moves through a CC machine. It is the predominant process route in a modern steel plant which

Steel Billet Continuous Casting Machine-Cooldo

2022-5-21 The steel continuous caster mainly consists of middle tank, crystallizer, vibrating mechanism, spindle rod, secondary cooling channel,a

Continuous Casting Machine

2022-3-29 The production process of continuouslycasting high temperature molten steel to billets with certain section and dimension is defined as continuous casting. The equipment used for this process is called as whole set of continuous casting machine. The mechanical, electrical and hydraulic integration of steel pouring equipment, body equipment of ...

Continuous Casting - an overview ScienceDirect Topics

The continuous casting process for steel is shown in Fig. 1 (second frame) and the close-up of the upper mold region is shown in Fig. 2.In this process, molten steel flows from a ladle, through a tundish into the mold. The tundish holds enough metal to provide a continuous flow to the mold, even during an exchange of ladles, which are supplied periodically from the steelmaking process.

continuous casting machine - 英中 – Linguee词典

equipment for a three- line continuous casting machine for the steel company, [...] ACINOX, in Las Tunas province, [...] in order to increase output from 250,000 tons of steel a year to 300,000 tons. daccess-ods.un. daccess-ods.un. 2009 年为拉斯图纳斯省钢铁公司 ACINOX 进行 3 线 连 铸机招标 ,以将钢 的年产量 ...

Continuous Casting Process - an overview ScienceDirect

The continuous casting process is shown in Figure 1.9.1.Steel is poured from the ladle into the tundish, which provides a constant head for molten steel to flow from the tundish into the mold via a submerged entry nozzle (SEN).The copper mold is water-cooled and the bottom of the mold is initially sealed by a dummy bar of steel. When steel is poured from the tundish to the mold, it

Continuous Casting (metallurgy) - Mechanical Engineering

2007-4-20 B.G. Thomas, “Continuous Casting”, Yearbook of Science and Technology, McGraw-Hill, 2004. 1 Continuous Casting (metallurgy) B.G. Thomas ... withdrawn down through the continuous casting machine and steady-state conditions evolve. The process then operates continuously for a period of one hour to several weeks, when the

Continuous Casting Machines - voestalpine Stahl Donawitz

2022-5-11 The new bloom continuous casting machine CC4 will be the new heart of steel production in Donawitz in 2020. This is the world's most modern and fully digitized system of its kind and offers premium quality through a globally unique combination of plant and process technology. Further continuous casting systems are the CC3 continuous casting ...

Continuous Casting Machine

2022-3-29 The production process of continuouslycasting high temperature molten steel to billets with certain section and dimension is defined as continuous casting. The equipment used for this process is called as whole set of continuous casting machine. The mechanical, electrical and hydraulic integration of steel pouring equipment, body equipment of ...

Quality Continuous Casting Machine Billet Casting

Continuous Casting Machine Parts. Rolling Mill Equipment.. All Products. Continuous Casting Machine (15) Billet Casting Machine (34) Steel Casting Machine (22) CCM Casting Machine (54) Slab Casting Machine (8) Continuous Casting Plant (8) Metallurgical Equipment (15) Continuous Cast Billets (8)

Continuous Casting Machine Atibir Industries

Continuous Casting Machine : Upcoming. Continuous Casting is the process whereby molten steel is solidified into a “semifinished” billet, bloom, or slab for subsequent rolling in the finishing mills. Prior to the introduction of Continuous

continuous casting machine - 英中 – Linguee词典

equipment for a three- line continuous casting machine for the steel company, [...] ACINOX, in Las Tunas province, [...] in order to increase output from 250,000 tons of steel a year to 300,000 tons. daccess-ods.un. daccess-ods.un. 2009 年为拉斯图纳斯省钢铁公司 ACINOX 进行 3 线 连 铸机招标 ,以将钢 的年产量 ...

What Is Continuous Casting? - Wirtz Manufacturing

2017-7-7 What Is Continuous Casting? Continuous casting allows metals and alloys to be stretched, shaped and solidified without the need for an interruption, reducing waste while improving yield, cost efficiency, and quality. Introduced into steel manufacturing the 1950s as an alternative to ingot molds, the continuous casting machine has now become a ...

Continuous Casting Process - an overview ScienceDirect

The continuous casting process is shown in Figure 1.9.1.Steel is poured from the ladle into the tundish, which provides a constant head for molten steel to flow from the tundish into the mold via a submerged entry nozzle (SEN).The copper mold is water-cooled and the bottom of the mold is initially sealed by a dummy bar of steel. When steel is poured from the tundish to the mold, it

Machine learning in continuous casting of steel: a state-of

2021-3-19 Continuous casting is the most important route for the production of steel today. Due to the physical, mechanical, and chemical components involved in the production, continuous casting is a very complex process, pushing conventional methods of monitoring and control to their limits. In recent years, this complexity and the increasing global competition created a

Products › Long › Billet casters Continuous Casting

Continuous Casting Machine solutions: Fastest, Best in Quality. Danieli Centro Met has the capability to supply billet casters for any potential requirement of the steel market. With a radii ranging from 6 to 12 m, our curved casting machines are able to produce billets in both square and round formats and in the range from 100 mm up to 200 mm ...

Continuous Casting of Steel

2003-7-29 Continuous casting is used to solidify most of the 750 million tons of steel produced in the world every year. Like most commercial processes, continuous casting involves many complex interacting phenomena. Most previous advances have been based on empirical knowledge gained from experimentation with the process.

Continuous Casting Machine Adtech China introduce

Continuous Casting Machine installation requirements. (1) The frame should be placed in sections and connected with bolts to form a whole. A plurality of hydraulic jacks are arranged under the frame, and the synchronous action can lift the frame to the required elevation and adjust the vertical and horizontal center of the frame.

Continuous Casting Machine Atibir Industries

Continuous Casting Machine : Upcoming. Continuous Casting is the process whereby molten steel is solidified into a “semifinished” billet, bloom, or slab for subsequent rolling in the finishing mills. Prior to the introduction of Continuous

Continuous Casting Machine – Technosteel

Continuous Casting Machine. Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a “semi-finished” billet, bloom, or slab for subsequent rolling in the finishing mills. Continuous casting is an energy-saving technique to cast the molten steel to a section shape or a certain size billet ...

continuous casting machine - 英中 – Linguee词典

equipment for a three- line continuous casting machine for the steel company, [...] ACINOX, in Las Tunas province, [...] in order to increase output from 250,000 tons of steel a year to 300,000 tons. daccess-ods.un. daccess-ods.un. 2009 年为拉斯图纳斯省钢铁公司 ACINOX 进行 3 线 连 铸机招标 ,以将钢 的年产量 ...

Billet Continuous Casting Machine/ Billet CCM

Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a “semi-finished” billet, bloom, or slab for subsequent rolling in the finishing mills. Continuous casting is an energy-saving technique to cast

Continuous Casting Process - an overview ScienceDirect

The continuous casting process is shown in Figure 1.9.1.Steel is poured from the ladle into the tundish, which provides a constant head for molten steel to flow from the tundish into the mold via a submerged entry nozzle (SEN).The copper mold is water-cooled and the bottom of the mold is initially sealed by a dummy bar of steel. When steel is poured from the tundish to the mold, it

Products › Long › Billet casters Continuous Casting

Continuous Casting Machine solutions: Fastest, Best in Quality. Danieli Centro Met has the capability to supply billet casters for any potential requirement of the steel market. With a radii ranging from 6 to 12 m, our curved casting machines are able to produce billets in both square and round formats and in the range from 100 mm up to 200 mm ...

Continuous Casting of Steel

2003-7-29 Continuous casting is used to solidify most of the 750 million tons of steel produced in the world every year. Like most commercial processes, continuous casting involves many complex interacting phenomena. Most previous advances have been based on empirical knowledge gained from experimentation with the process.

Continuous casting of aluminium

2020-2-27 for strip to be hot rolled after leaving the casting machine (gauge between 20 mm and 40 mm) for thin gauge casting (gauge under 3 mm) Another distinguishing feature is the type of the caster (see chapter 3). 3210.03 Wire bar casting The continuous casting of wire bars is also of great economic importance. As is the case

CONTINUOUS CASTING MACHINE 日本語 意味 - 日本語訳

の連続鋳造機械 。. Mm copper continuous casting machine for copper rod make. Mmの銅の棒のための銅の 連続鋳造機械は 作ります。. Mm 5000t Upward Continuous Casting Machine for bright and long oxygen- free copper rod. Mmの5000t明るく、長い酸素-.

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت